New Products

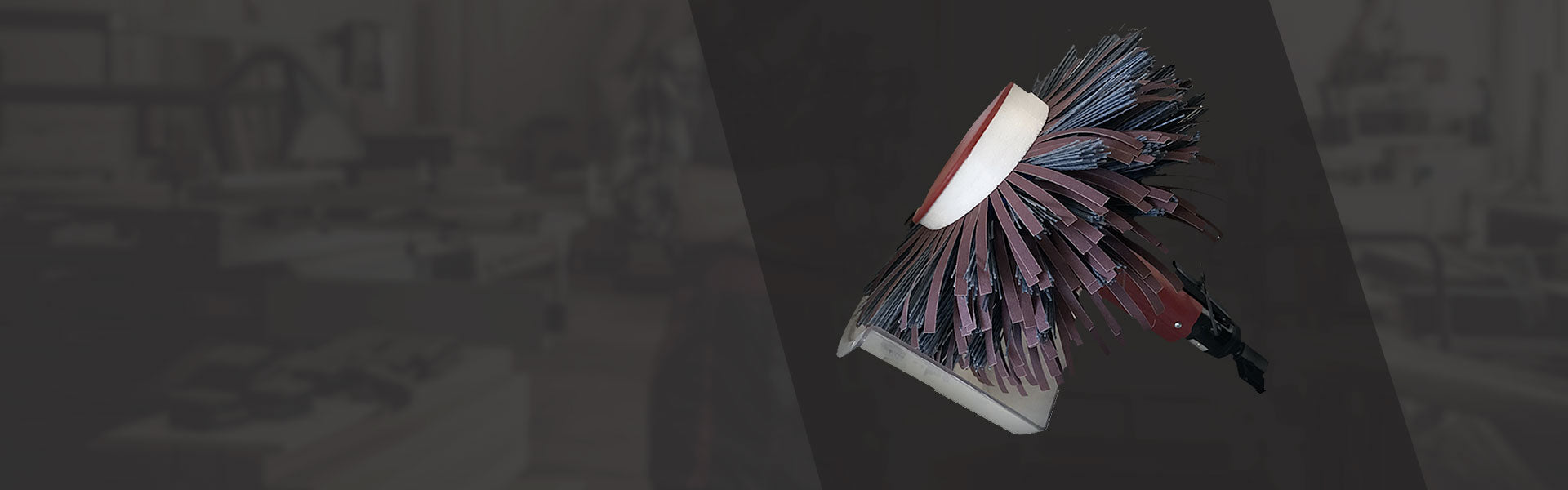

F15 - QuickWood Air Tool with Optional 8" Head

F6 - QuickWood Air Tool with Optional 4" Head

F3 - QuickWood Air Tool with Optional 2" Head

Quick Shipping

Shop our line of abrasives

Latest Deals

Free Shipping USA

on all orders over $75

Free Shipping Europe

on all orders over $500

Free Shipping Middle East

on all orders over $1000